Making Biofuels Part 1

Table of Contents

- Making Biofuels from Energy Crops-Feedstock Composition and Biochemical Conversion

- Conventional Feedstocks

- Plant Structural Components

- Lignocellulosic Feedstocks - Part 1

- Lignocellulosic Feedstocks - Part 2

- Corn vs. Biomass Conversion to Ethanol

- Biochemical Conversion Sugar-Platform Fermentation

- Biochemical Conversion Pretreatment and Hydrolysis

- Biochemical Conversion Cell-Wall Recalcitrance

- Biochemical Conversion Hydrolysis, Saccharification, Fermentation

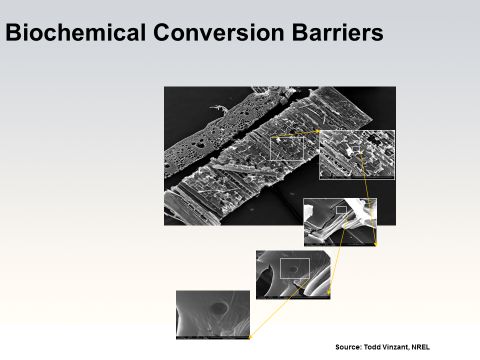

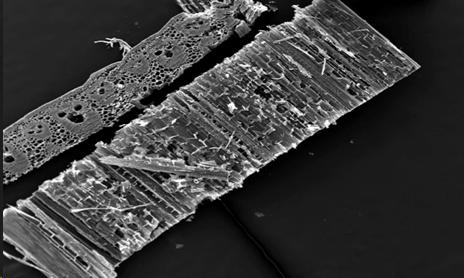

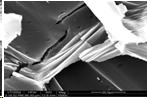

- Biochemical Conversion Barriers

- Vocabulary

Text and Images from Slide

Biochemical Conversion Barriers

Source: Todd Vinzant, NREL